студ . 26, 2025 08:41

Back to list

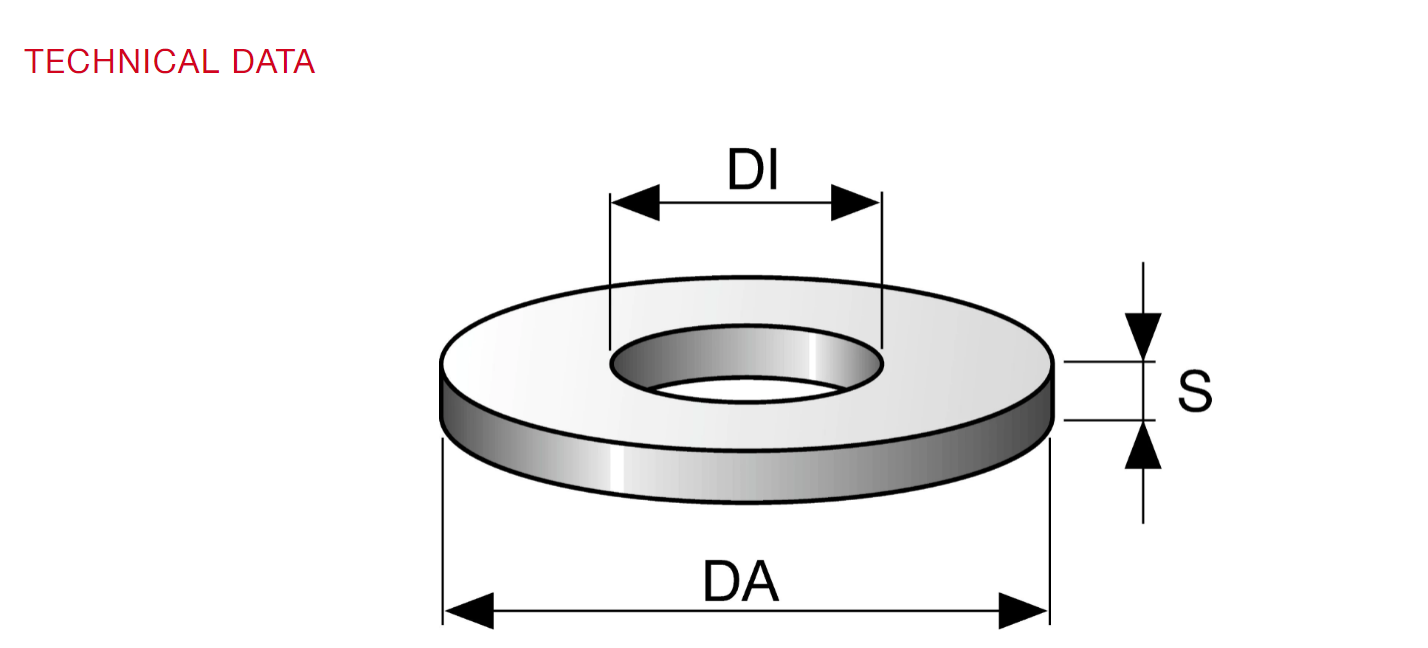

DIN125 Flat Washer ,ZP , YZP, BLACK , PLAIN

When procuring bolts, washers, and lock washers, understanding the intricate details of each component and how they contribute to a secure and reliable fastening solution is essential. This article delves into the practical insights and expert knowledge necessary to navigate the complexities of these components, drawing from years of industry experience and authoritative technical expertise.

When ordering these components, an authoritative source is pivotal. Reliable suppliers with industry authority not only offer a wide range of products but also provide technical support and guidance based on the latest standards and practices. Trustworthiness in this context stems from vendors with proven track records, certified products, and comprehensive warranties. In practice, gaining hands-on experience with these components can significantly bolster one’s understanding. Fastener failure is often due to minor oversights, such as the misuse of washers or incorrect torque application. Therefore, having firsthand experience and learning from real-world applications can prevent such failures, enabling a more effective deployment of bolts, washers, and lock washers. Additionally, the material composition of these components - whether stainless steel, carbon steel, or alloy - directly influences their performance and suitability for specific environments. Knowledge in metallurgy and environmental resistance is employed when selecting the appropriate combination of materials for enduring performance in diverse conditions. For highly corrosive environments, stainless steel or coated finishes may be recommended, highlighting the authoritative background necessary to make these determinations. To optimize the ordering process for bolts, washers, and lock washers, leveraging modern technology platforms and supply chain innovations is advisable. Digital solutions provide real-time inventory data, predictive delivery times, and customization options to tailor the procurement process to specific project needs. This advanced approach not only saves time but also increases the reliability of obtaining the right materials efficiently. In conclusion, navigating the ordering of bolts, washers, and lock washers necessitates a blend of technical expertise, real-world experience, and an understanding of authoritative industry standards. By considering factors such as material composition, typology of washers, and the credibility of suppliers, one can ensure a robust and durable fastening solution. Trust in the procurement process is built through informed decisions, guided by expert insights and reliable technology, thus fulfilling the demand for quality and performance in any mechanical or construction endeavor.

When ordering these components, an authoritative source is pivotal. Reliable suppliers with industry authority not only offer a wide range of products but also provide technical support and guidance based on the latest standards and practices. Trustworthiness in this context stems from vendors with proven track records, certified products, and comprehensive warranties. In practice, gaining hands-on experience with these components can significantly bolster one’s understanding. Fastener failure is often due to minor oversights, such as the misuse of washers or incorrect torque application. Therefore, having firsthand experience and learning from real-world applications can prevent such failures, enabling a more effective deployment of bolts, washers, and lock washers. Additionally, the material composition of these components - whether stainless steel, carbon steel, or alloy - directly influences their performance and suitability for specific environments. Knowledge in metallurgy and environmental resistance is employed when selecting the appropriate combination of materials for enduring performance in diverse conditions. For highly corrosive environments, stainless steel or coated finishes may be recommended, highlighting the authoritative background necessary to make these determinations. To optimize the ordering process for bolts, washers, and lock washers, leveraging modern technology platforms and supply chain innovations is advisable. Digital solutions provide real-time inventory data, predictive delivery times, and customization options to tailor the procurement process to specific project needs. This advanced approach not only saves time but also increases the reliability of obtaining the right materials efficiently. In conclusion, navigating the ordering of bolts, washers, and lock washers necessitates a blend of technical expertise, real-world experience, and an understanding of authoritative industry standards. By considering factors such as material composition, typology of washers, and the credibility of suppliers, one can ensure a robust and durable fastening solution. Trust in the procurement process is built through informed decisions, guided by expert insights and reliable technology, thus fulfilling the demand for quality and performance in any mechanical or construction endeavor.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News