студ . 23, 2025 05:20

Back to list

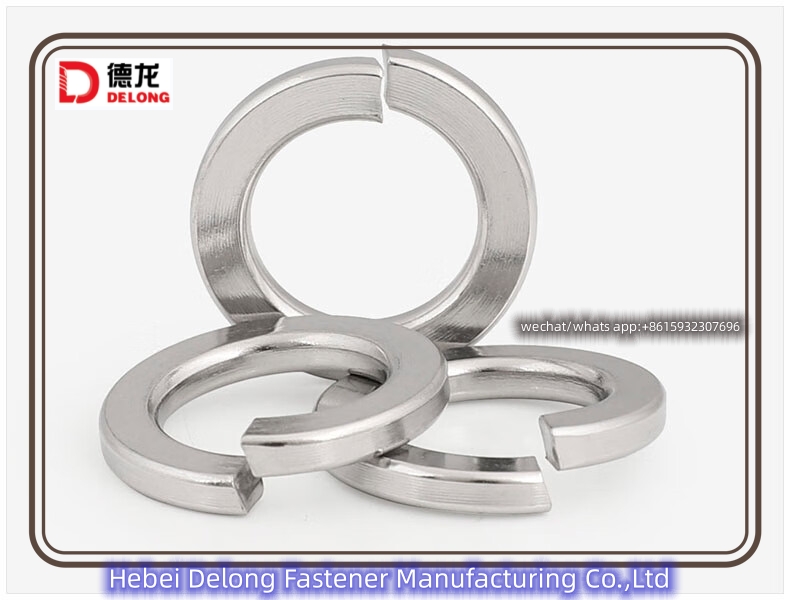

ASTM F436 Flat Washer

In the world of mechanical assemblies, every component plays a significant role, and the [1/2 SAE Flat Washer] is no exception. Understanding its meticulous design and dimensions is imperative for achieving optimal performance in various applications. This article aims to provide an in-depth overview of the 1/2 SAE Flat Washer dimensions, drawing from industry insights and expert recommendations to enhance your product knowledge and application efficiency.

Where material composition is concerned, 1/2 SAE Flat Washers are commonly manufactured from high-strength, corrosion-resistant materials such as stainless steel, carbon steel, or brass. Each material brings its own set of advantages, with stainless steel offering excellent resistance to rust and corrosion, carbon steel providing superior strength, and brass contributing durability along with aesthetic value. The application scope of the 1/2 SAE Flat Washer is as broad as it is distinct. These washers are instrumental in automotive, engineering, and manufacturing industries where reliability and precision are non-negotiable. From securing engine components to safeguarding sensitive electronics, the versatility of these washers cannot be overstated. They are designed to withstand high pressure and varying environmental conditions, making them a go-to solution for engineers striving for consistency and reliability. Utilizing 1/2 SAE Flat Washers not only simplifies the assembly process but also significantly minimizes the risk of material fatigue and wear over time. By evenly distributing force, the washers help maintain the integrity of the joints, even under dynamic loads. This reliability translates to prolonged equipment life cycles and reduced maintenance costs, an attractive prospect for any industrial operation. In conclusion, the 1/2 SAE Flat Washer's dimensions and material composition are reflections of rigorous industry standards aimed at providing maximum utility. For those involved in assembly design and component selection, understanding these dimensions is essential. With the right knowledge, technicians and engineers can maximize the performance and longevity of their projects by ensuring each component, including the humble 1/2 SAE Flat Washer, is used to its full potential. As the unsung hero in countless mechanical assemblies, this small yet mighty component has proven to be indispensable in ensuring structural integrity and operational efficiency.

Where material composition is concerned, 1/2 SAE Flat Washers are commonly manufactured from high-strength, corrosion-resistant materials such as stainless steel, carbon steel, or brass. Each material brings its own set of advantages, with stainless steel offering excellent resistance to rust and corrosion, carbon steel providing superior strength, and brass contributing durability along with aesthetic value. The application scope of the 1/2 SAE Flat Washer is as broad as it is distinct. These washers are instrumental in automotive, engineering, and manufacturing industries where reliability and precision are non-negotiable. From securing engine components to safeguarding sensitive electronics, the versatility of these washers cannot be overstated. They are designed to withstand high pressure and varying environmental conditions, making them a go-to solution for engineers striving for consistency and reliability. Utilizing 1/2 SAE Flat Washers not only simplifies the assembly process but also significantly minimizes the risk of material fatigue and wear over time. By evenly distributing force, the washers help maintain the integrity of the joints, even under dynamic loads. This reliability translates to prolonged equipment life cycles and reduced maintenance costs, an attractive prospect for any industrial operation. In conclusion, the 1/2 SAE Flat Washer's dimensions and material composition are reflections of rigorous industry standards aimed at providing maximum utility. For those involved in assembly design and component selection, understanding these dimensions is essential. With the right knowledge, technicians and engineers can maximize the performance and longevity of their projects by ensuring each component, including the humble 1/2 SAE Flat Washer, is used to its full potential. As the unsung hero in countless mechanical assemblies, this small yet mighty component has proven to be indispensable in ensuring structural integrity and operational efficiency.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News