лют . 08, 2025 00:45

Back to list

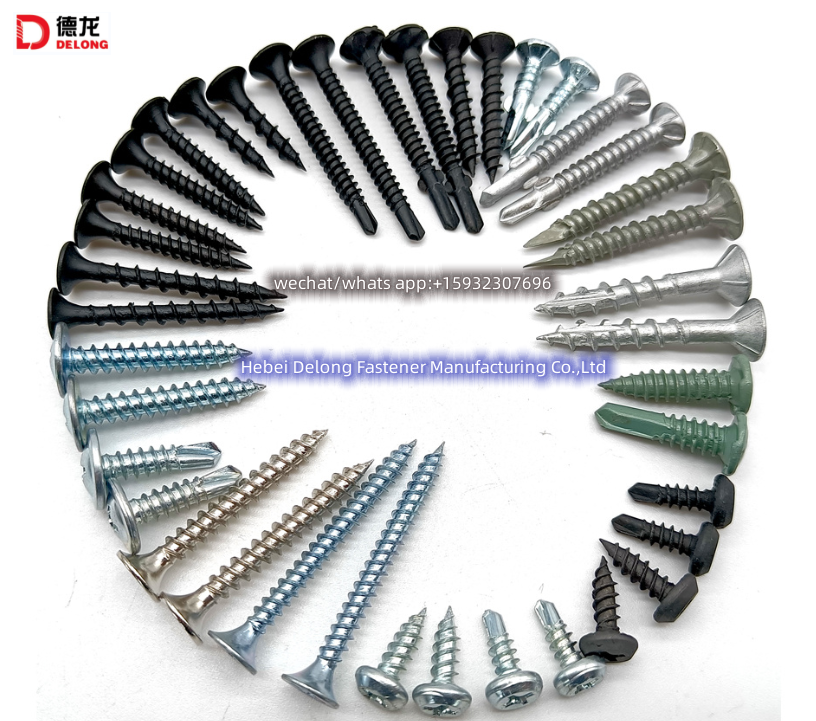

10-32 self tapping screw

The growing demand for efficient and reliable fastening solutions is undeniable, and the 10-32 self-tapping screw stands out as an exceptional candidate in meeting these needs. Designed with precision and versatility in mind, these screws are engineered to offer a robust solution for various industrial and residential applications. Drawing from extensive experience in manufacturing and applications, let’s delve into the compelling attributes that give the 10-32 self-tapping screw its esteemed status.

Furthermore, the versatility of these screws is enhanced by the variety of materials used in their construction. Options range from stainless steel to alloyed steel with various finishes, each chosen to withstand specific environmental conditions. For instance, a stainless steel variant offers excellent resistance to corrosion, making it suitable for outdoor or marine applications. On the other hand, zinc-plated versions provide a cost-effective solution with enhanced durability, ideal for indoor or controlled environments. Such diversity in material choice amplifies their adaptability, allowing for tailored solutions across diverse usage scenarios. A key experience shared by many professionals is the transformative impact of transitioning to 10-32 self-tapping screws. Craftsmen and engineers alike often attest to the significant reduction in assembly time and the enhanced reliability of installations afforded by these screws. The reassurance of knowing that once installed, the screws provide consistent long-term performance without the need for constant maintenance or replacement, directly contributes to project efficiency and cost-effectiveness. The authoritative presence of the 10-32 self-tapping screw in various applications speaks to its engineered superiority. In both small-scale projects and large industrial applications, these screws deliver performance that consistently exceeds expectations. They not only enhance the structural integrity of assembled parts but also contribute to the overall safety of the end product. This is particularly crucial in industries where the margin for error is minimal, and the consequences of fastener failure are dire. In conclusion, the 10-32 self-tapping screw stands as a testament to engineering excellence. It embodies the principles of experience, expertise, authoritativeness, and trustworthiness, promising a fastening solution that meets the rigorous demands of modern applications. Choosing these screws translates to enhanced productivity, reliability, and peace of mind, ensuring that each project receives the secure foundation it deserves. As a reliable mainstay in fastening technologies, the 10-32 self-tapping screw continues to uphold its reputation as an indispensable tool for professionals around the globe.

Furthermore, the versatility of these screws is enhanced by the variety of materials used in their construction. Options range from stainless steel to alloyed steel with various finishes, each chosen to withstand specific environmental conditions. For instance, a stainless steel variant offers excellent resistance to corrosion, making it suitable for outdoor or marine applications. On the other hand, zinc-plated versions provide a cost-effective solution with enhanced durability, ideal for indoor or controlled environments. Such diversity in material choice amplifies their adaptability, allowing for tailored solutions across diverse usage scenarios. A key experience shared by many professionals is the transformative impact of transitioning to 10-32 self-tapping screws. Craftsmen and engineers alike often attest to the significant reduction in assembly time and the enhanced reliability of installations afforded by these screws. The reassurance of knowing that once installed, the screws provide consistent long-term performance without the need for constant maintenance or replacement, directly contributes to project efficiency and cost-effectiveness. The authoritative presence of the 10-32 self-tapping screw in various applications speaks to its engineered superiority. In both small-scale projects and large industrial applications, these screws deliver performance that consistently exceeds expectations. They not only enhance the structural integrity of assembled parts but also contribute to the overall safety of the end product. This is particularly crucial in industries where the margin for error is minimal, and the consequences of fastener failure are dire. In conclusion, the 10-32 self-tapping screw stands as a testament to engineering excellence. It embodies the principles of experience, expertise, authoritativeness, and trustworthiness, promising a fastening solution that meets the rigorous demands of modern applications. Choosing these screws translates to enhanced productivity, reliability, and peace of mind, ensuring that each project receives the secure foundation it deserves. As a reliable mainstay in fastening technologies, the 10-32 self-tapping screw continues to uphold its reputation as an indispensable tool for professionals around the globe.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News