Yellow Zinc Plated Chipboard Screw Supplier for Global Export Needs

Exploring the World of Yellow Zinc Plated Chipboard Screw Exporters

In the vast landscape of construction and manufacturing, fastening solutions play a pivotal role in ensuring structural integrity and product longevity. Among the various types of fasteners available in the market, chipboard screws, particularly those that are yellow zinc plated, have gained significant popularity due to their corrosion resistance and aesthetic appeal. This article aims to provide an in-depth look at yellow zinc plated chipboard screw exporters, their significance in global trade, and the factors that make them a preferred choice for many industries.

Understanding Chipboard Screws

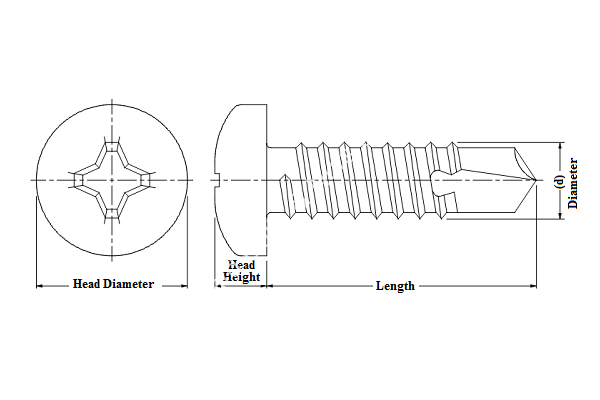

Chipboard screws are specially designed fasteners used primarily for connecting particle board and chipboard materials. Their unique design, characterized by sharp threads and a flat or countersunk head, allows for enhanced grip and minimizes the risk of splitting the board materials. The yellow zinc plating, a finish that provides both durability and a shiny appearance, further enhances the longevity of these screws by protecting them from rust and corrosion.

The Role of Exporters

Exporters play a crucial role in the distribution of yellow zinc plated chipboard screws to various markets around the world. They bridge the gap between manufacturers and consumers, ensuring that high-quality fasteners are readily available to builders, furniture manufacturers, and DIY enthusiasts. The importance of exporters cannot be overstated; they not only provide logistics support but also ensure compliance with international quality standards, making it easier for businesses to source reliable products.

Demand in the Global Market

yellow zinc plated chipboard screw exporter

The demand for yellow zinc plated chipboard screws is on the rise in various industries, including furniture manufacturing, construction, and home renovation. Their aesthetic quality, combined with functional advantages, makes them an attractive option for a wide range of applications. The increasing focus on sustainable practices and the use of engineered wood products also contribute to the heightened demand for chipboard screws, as they are essential for assembling and securing these materials.

Advantages of Yellow Zinc Coating

The yellow zinc plating on chipboard screws offers several advantages. First and foremost, it provides excellent resistance to corrosion, which is critical in environments that are prone to moisture. This coating helps the screws maintain their strength and appearance over time, reducing the need for replacements and thus contributing to cost savings. Furthermore, the bright yellow hue of the zinc plating not only adds a decorative touch but also serves as a visual identifier for quality fasteners.

Choosing the Right Exporter

When seeking a reliable yellow zinc plated chipboard screw exporter, several factors should be considered. Quality assurance is paramount; exporters should have certifications that validate their products meet international standards. Additionally, evaluating the exporter’s reputation through reviews and testimonials can provide insight into their reliability and the quality of their offering. Furthermore, understanding the supply chain logistics, including lead times and shipping costs, is essential for ensuring timely delivery and competitive pricing.

Conclusion

Yellow zinc plated chipboard screws are an integral part of modern construction and manufacturing practices. Their unique properties, coupled with the expertise of dedicated exporters, enable businesses to meet their fastening needs efficiently. As industries continue to evolve and demand for high-quality fasteners grows, the role of yellow zinc plated chipboard screw exporters will remain vital in shaping the future of construction and assembly worldwide. By choosing the right partners in this sector, businesses can not only ensure product quality but also enhance their operational efficiency and market competitiveness.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024