Manufacturers Guide to Optimal Hole Size for Self Tapping Screws

Understanding Self-Tapping Screw Hole Sizes A Guide for Manufacturers

Self-tapping screws are essential components in various industries, from construction to electronics. These screws are designed to create their own mating threads in the material they are driven into, allowing for efficient assembly and secure fastening without the need for pre-drilled holes. However, to ensure optimal performance, it is crucial for manufacturers to understand the significance of hole sizes when working with self-tapping screws.

What Are Self-Tapping Screws?

Self-tapping screws are typically made from materials such as steel, stainless steel, or brass, and they come with a sharp point that enables them to penetrate various materials, including wood, metal, and plastic. The unique design of these screws allows them to tap their threads as they are installed, resulting in a tight fit that can withstand vibration and shear forces.

Importance of Hole Size

The size of the hole into which a self-tapping screw is driven plays a significant role in its performance. A correctly sized hole ensures that the screw can engage and form threads properly, achieving the desired clamping force. If the hole is too large, the screw may not grip adequately, leading to loosening and potential failure of the assembly. Conversely, if the hole is too small, the screw may be difficult to install and could strip the material or break altogether.

Factors Affecting Hole Size

Several factors influence the optimal hole size for self-tapping screws, including

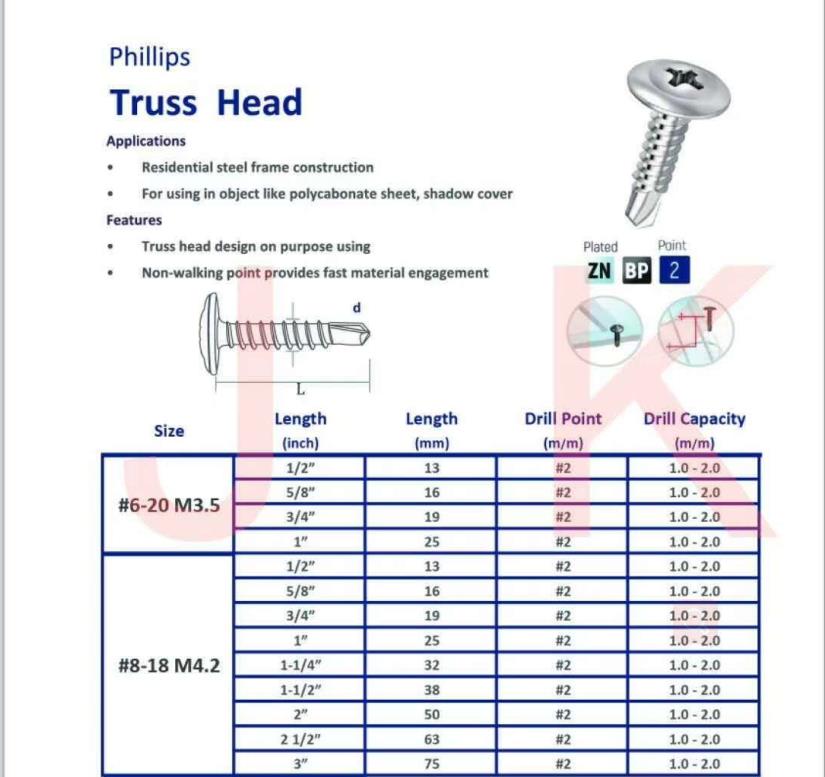

1. Screw Diameter The diameter of the screw itself is the primary factor determining hole size. Manufacturers should refer to the specifications provided by screw suppliers to determine the appropriate hole diameter corresponding to each screw size.

2. Material Type Different materials require different hole sizes due to variations in density, hardness, and elasticity. For example, a self-tapping screw used in softwood may require a larger pilot hole than the same screw used in metal.

self tapping screw hole size manufacturers

4. Application The intended application of the assembly can also dictate hole size. Screws used in applications involving high shear or tensile forces may benefit from tighter hole tolerances to ensure maximum grip.

Recommended Practices for Manufacturers

To achieve the best results when using self-tapping screws, manufacturers should consider implementing the following practices

1. Consult Manufacturer Specifications Always refer to the screw manufacturer's guidelines regarding hole size to ensure compatibility. This information typically includes recommended hole diameters for various materials.

2. Conduct Material Testing Before finalizing designs, conduct tests on the specific materials to evaluate how they interact with the self-tapping screws. This will help fine-tune hole sizes for different applications.

3. Use Quality Tools Invest in high-quality drilling and driving tools to achieve precise hole sizes. Poorly drilled holes can lead to inconsistent threads and compromise the integrity of the assembly.

4. Monitor Installation Procedures Ensure that the installation process is standardized and that operators are trained in the correct installation techniques for self-tapping screws, as improper handling can lead to hole size issues.

Conclusion

In summary, understanding self-tapping screw hole sizes is vital for manufacturers looking to enhance the performance and reliability of their products. By considering screw dimensions, material characteristics, and application requirements, manufacturers can ensure optimal fastening solutions that meet industry standards and client expectations. With the right practices in place, self-tapping screws can significantly contribute to the durability and functionality of assemblies across various sectors.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024