m3 countersunk self tapping screw company

The Importance of M3 Countersunk Self-Tapping Screws for Modern Manufacturing

In today's fast-paced manufacturing landscape, the need for reliable, effective fastening solutions is paramount. Among the myriad of fastening options available, M3 countersunk self-tapping screws have gained notable recognition for their versatility and efficiency. These screws serve essential functions across various industries, from construction to electronics, due to their unique design and functionality.

What are M3 Countersunk Self-Tapping Screws?

M3 countersunk self-tapping screws are fasteners with a diameter of 3mm that possess a conical head designed to sit flush with the surface when installed. This particular design reduces the likelihood of snagging or catching on objects, making it ideal for applications where a smooth finish is required. Self-tapping screws are engineered to create their own hole as they are driven into materials, eliminating the need for pre-drilling. This feature not only saves time but also simplifies assembly processes, making them a preferred choice for many professionals.

Key Advantages

1. Efficiency of Installation One of the most significant advantages of M3 countersunk self-tapping screws is their ease of installation. The self-tapping feature allows users to drive the screw directly into the material without the need for additional tools, which speeds up the process. This efficiency is crucial in high-volume manufacturing settings where time is money.

2. Versatility These screws can be used in a variety of materials, including wood, plastic, and thin metals. This versatility makes M3 countersunk self-tapping screws suitable for diverse applications, from assembling furniture to fixing electronic components. Their multi-material compatibility enhances their usability across different industries.

3. Aesthetic Appeal The countersunk design allows the screw head to sit below the surface of the material, providing a cleaner and more polished appearance. This feature is particularly important in consumer products, where presentation can affect customer perception and satisfaction.

4. Strong Hold M3 countersunk self-tapping screws provide a strong and secure hold, which is crucial in ensuring the integrity and durability of the assembly. Their ability to form threads within the material contributes to their reliability in keeping components securely fastened, even in high-stress applications.

m3 countersunk self tapping screw company

Industrial Applications

The relevance of M3 countersunk self-tapping screws can be observed across various industries. In the electronics sector, these screws are commonly used to secure components within devices, where space and weight are concerns. They ensure that circuit boards and other parts are firmly held in place without adding unnecessary bulk.

In the construction industry, these screws are often employed to fasten fixtures and fittings due to their ability to penetrate materials effortlessly. They are favored in situations where a flush finish is desired, such as in cabinetry and paneling.

Moreover, the automotive industry also makes extensive use of M3 countersunk self-tapping screws. They are essential in assembling vehicles where fasteners contribute to the vehicle's structural integrity while maintaining an unobtrusive appearance.

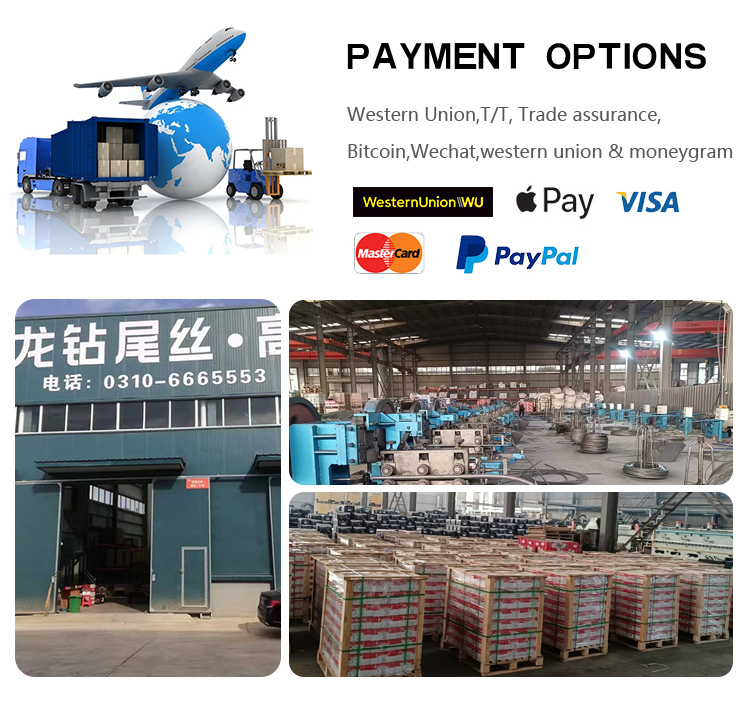

Choosing the Right Supplier

Selecting a reputable supplier for M3 countersunk self-tapping screws is crucial for ensuring quality. A reliable company should offer a variety of materials, such as stainless steel or zinc-plated options, to suit different environmental requirements. Additionally, they should provide comprehensive specifications to help manufacturers choose the best fasteners for their specific needs.

Conclusion

M3 countersunk self-tapping screws are indispensable components in modern manufacturing. Their efficiency, versatility, aesthetic appeal, and strong holding capabilities make them an ideal choice across a wide range of applications. As industries continue to evolve and demand more from their fastening solutions, M3 countersunk self-tapping screws will undoubtedly remain a staple in the toolkit of professionals globally. By choosing the right supplier, manufacturers can ensure that they have access to high-quality fastening solutions that enhance their products' durability and performance.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024