Optimal Drywall Screw Spacing for Wall Installation Tips and Best Practices

Understanding Famous Drywall Screw Spacing for Wall Installation

When it comes to drywall installation, one of the key factors that contribute to a successful project is the precise spacing of drywall screws. Proper screw spacing not only ensures that the drywall is securely fastened but also affects the overall finish and stability of the wall. This article delves into the best practices for drywall screw spacing, focusing on the commonly referenced standards and techniques employed by professionals.

Importance of Proper Screw Spacing

Proper screw spacing is crucial for several reasons. First and foremost, it aids in mitigating the risk of sagging and cracking over time, which can occur if the drywall is inadequately supported. Furthermore, correct screw placement improves the overall rigidity of the wall, providing a solid foundation for finishes such as paint or wallpaper.

Additionally, adhering to the recommended spaces helps prevent issues during the taping and joint finishing process. Enough support ensures that the seams between drywall sheets can be smoothly joined without detecting irregularities or bulges in the surface.

Standard Screw Spacing Guidelines

The National Gypsum Association and other industry experts provide standardized guidelines for drywall screw spacing

. Typically, for ceilings, screws should be spaced no more than 12 inches apart along the perimeter and 12 inches on center for the field (the middle area of the drywall sheet).For walls, the spacing is typically a bit wider. Here, screws should be placed no more than 16 inches apart along the studs in the field of the wall. At the edges of the drywall, the screws should be placed every 8 inches. These measurements allow for sufficient anchoring to the studs, thus enhancing the overall strength of the installation.

famous drywall screw spacing wall

Types of Screws and Installation Techniques

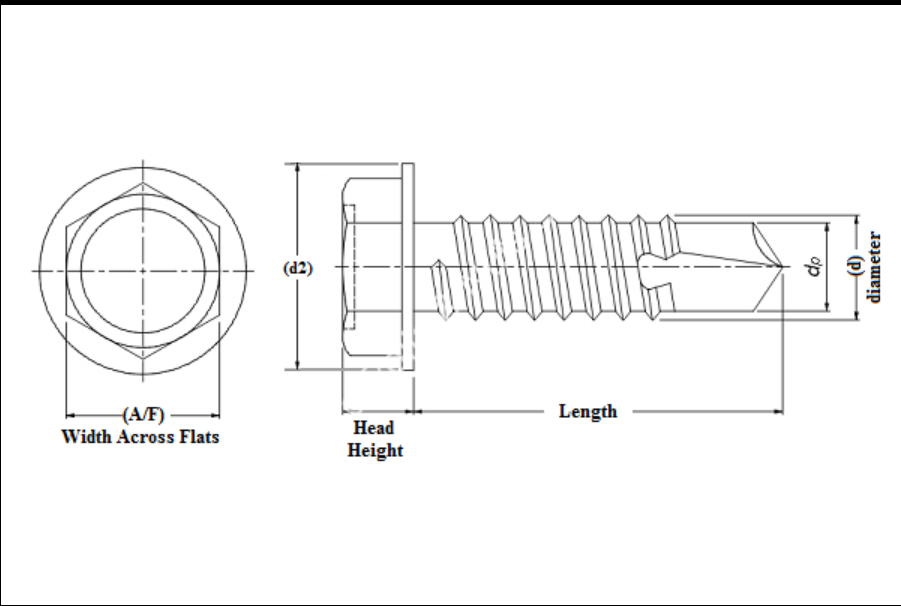

The choice of screws and their installation plays a significant role in the efficacy of the project. Drywall screws are specifically designed for fastening drywall sheets to wooden or metal studs, and they have a sharp point to penetrate the material easily. The most common type used is the coarse-thread screw for wood studs and fine-thread screws for metal studs.

When installing, it is essential to drive the screws in straight and flush with the surface of the drywall without breaking the paper face. The head of the screw should create a minor indentation in the drywall, which allows for proper finishing with joint compound.

Common Mistakes to Avoid

While the guidelines may seem straightforward, there are common mistakes that DIYers and even experienced contractors can make. One of the biggest pitfalls is failing to use the correct screw length. For ½-inch drywall, a screw length of 1 ¼ inches typically suffices, while 5/8-inch drywall may require 1 5/8 inches or more.

Another mistake is inconsistent spacing. It is critical to measure accurately and keep the spacing uniform. Using a chalk line can help in ensuring that the screws are evenly placed along the runs.

Conclusion

Incorporating proper drywall screw spacing is an essential aspect of successful drywall installation. Following recommended guidelines enhances the durability and aesthetic appeal of walls, ensuring they stand the test of time. Whether you are a seasoned professional or a DIY enthusiast, understanding these standards will undoubtedly contribute to achieving a high-quality finish in your drywall projects. Remember, attention to detail in the initial installation can prevent numerous headaches down the line.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024