custom flat washer din125

Understanding Custom Flat Washers The Din 125 Standard

Flat washers are crucial components in various mechanical and construction applications, serving to distribute loads, reduce friction, and provide a smooth surface for fasteners. Among the many standards governing these essential components, the DIN 125 standard is one of the most widely recognized. This article explores custom flat washers according to the DIN 125 specification, shedding light on their importance and applications in industrial settings.

Understanding Custom Flat Washers The Din 125 Standard

One of the key advantages of custom flat washers, especially those made to the DIN 125 standard, is their versatility. They can be manufactured from various materials, including steel, stainless steel, nylon, and other composite materials. This variety allows engineers and designers to choose washers that meet specific environmental and mechanical needs, such as corrosion resistance, strength, and weight considerations. For instance, stainless steel washers are often preferred in applications exposed to moisture, while nylon washers can be used in applications requiring electrical insulation.

custom flat washer din125

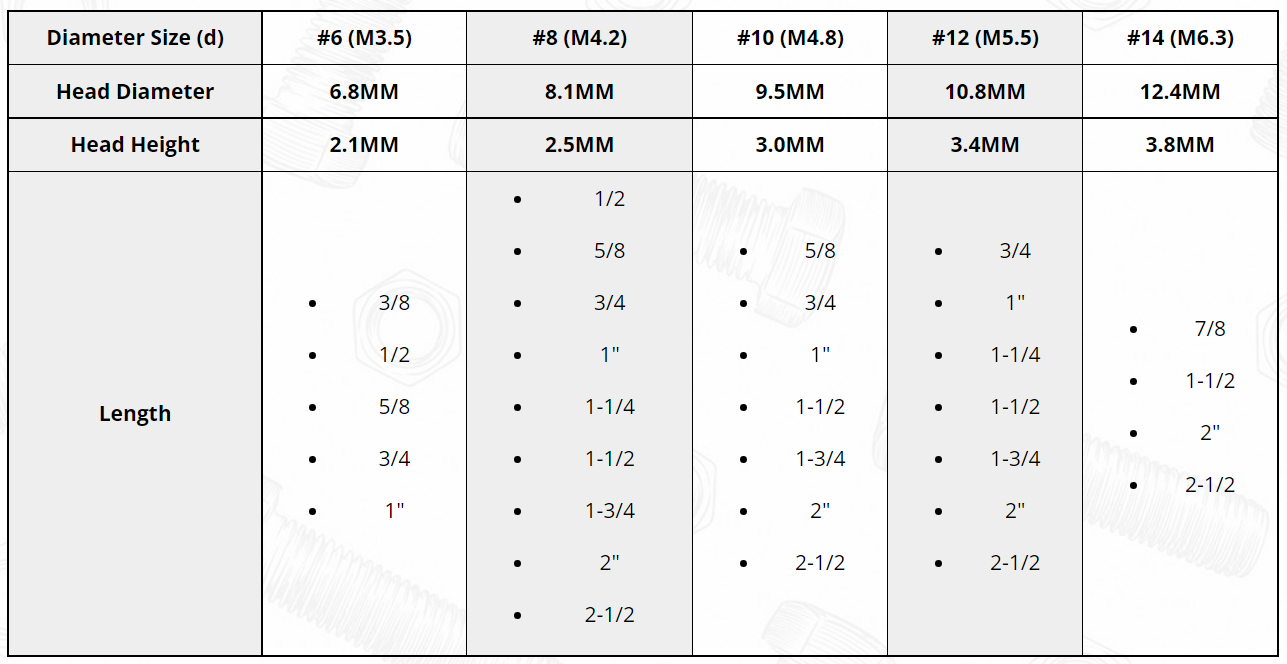

Custom flat washers can be produced in different sizes and thicknesses according to project requirements. The DIN 125 specification provides guidelines for dimensions and tolerances, ensuring consistency and compatibility with corresponding fasteners. This adaptability makes it easier for manufacturers to tailor solutions that meet unique project needs, enhancing overall operational efficiency.

In industries such as automotive, aerospace, and construction, the use of DIN 125 custom flat washers is ubiquitous. These washers help in various applications, from securing engine components to stabilizing structural connections. By ensuring a proper fit between components, custom flat washers contribute to the overall safety and performance of the final product.

In conclusion, custom flat washers made to the DIN 125 standard play an essential role in the functionality and reliability of numerous mechanical systems. Their ability to distribute loads, reduce wear, and prevent loosening makes them indispensable in many industrial applications. For engineers and designers, understanding the benefits and specifications of these washers is crucial in selecting the right products for their projects, ultimately leading to enhanced performance and durability of the assemblies they create.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024