Suppliers of Self-Tapping Screws Designed for 1-4 Steel Applications

Self-Tapping Screws for 1.04 Steel A Comprehensive Guide for Suppliers

In the world of construction and manufacturing, the reliability of fasteners is crucial. Among the various types of screws available, self-tapping screws have become increasingly popular due to their unique design and functionality. This article will explore the specifications, advantages, and considerations for suppliers of self-tapping screws, particularly those designed for use with 1.04 steel.

Understanding Self-Tapping Screws

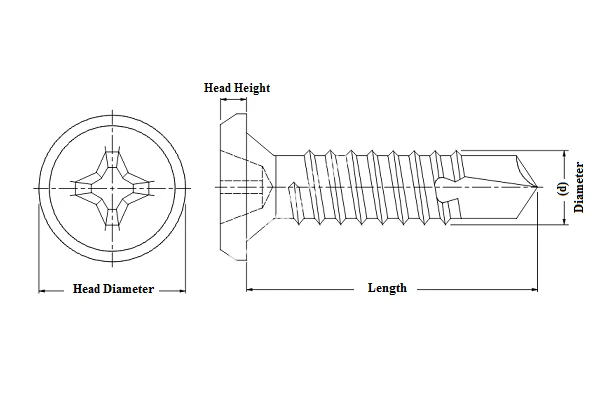

Self-tapping screws are designed to tap their own hole as they are driven into materials, eliminating the need for pre-drilling in many applications. This feature makes them an excellent choice for various metals, including low carbon steel like 1.04 steel, which is widely used in a range of industrial applications due to its good weldability and tensile strength.

Choosing the Right Type

There are several types of self-tapping screws, including

1. Thread-Forming Screws These screws create threads in the base material without removing any material. They are particularly beneficial in softer materials. 2. Thread-Cutting Screws Designed to cut away material as they are installed, these screws are suitable for harder materials and create a precise hole.

3. Self-Drilling Screws Also known as Tek screws, these have a drill tip that enables them to bore through the material without the need for a pilot hole.

For applications involving 1.04 steel, suppliers often provide a mix of thread-cutting and self-drilling screws due to their effectiveness in penetrating harder materials.

Benefits of Self-Tapping Screws

1. Time Efficiency The ability of self-tapping screws to eliminate the need for pre-drilling can significantly reduce installation time, making them an attractive option in fast-paced industrial environments.

2. Strong Holding Power Properly designed self-tapping screws can offer significant holding power, especially when used in thicker gauges of steel.

3. Versatility These screws can be used in a wide range of applications from HVAC systems to automotive industries, making them a staple for many suppliers.

self tapping screw for 1 4 steel suppliers

Specifications for 1.04 Steel Applications

When it comes to sourcing or supplying self-tapping screws for use with 1.04 steel, certain specifications must be adhered to

- Material Quality The screws should ideally be manufactured from materials with corrosion resistance, such as zinc-plated steel or stainless steel, to ensure longevity, especially in outdoor or humid environments.

- Coating A protective coating can help prevent corrosion, thus increasing the screws' lifespan and reliability.

- Thread Design For optimal performance in 1.04 steel, a coarse thread design is often recommended as it provides better grip and reduces the risk of stripping.

- Size Options Suppliers should offer a variety of sizes to cater to different thicknesses of steel applications and ensure compatibility.

Supplier Considerations

For suppliers, understanding the specific needs of their customer base is critical. This involves

- Inventory Management Keeping a diverse inventory of sizes and thread designs to meet fluctuating demands.

- Quality Assurance Implementing rigorous quality control measures during the manufacturing process to minimize defects and ensure consistent performance.

- Customer Education Providing resources or training for customers on the best practices for using self-tapping screws with 1.04 steel can enhance overall satisfaction and increase repeat business.

- Sustainability Practices More customers are gravitating towards suppliers who demonstrate environmentally responsible practices in their sourcing and manufacturing processes.

Conclusion

Self-tapping screws designed for use with 1.04 steel represent an essential component in the construction and manufacturing industries. Their ease of use, efficiency, and strong holding power make them a preferred choice for many applications. By focusing on high-quality products, understanding customer needs, and implementing sustainable practices, suppliers can ensure they meet the growing demand for self-tapping screws in today’s competitive market. Looking ahead, the evolution of materials and manufacturing technologies may enhance these fasteners' capabilities, promising future opportunities for innovation and growth in the industry.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024