Guide to Self-Tapping Screws Chart and Trusted Suppliers for Your Projects

Understanding Self-Tapping Screws A Comprehensive Guide for Suppliers

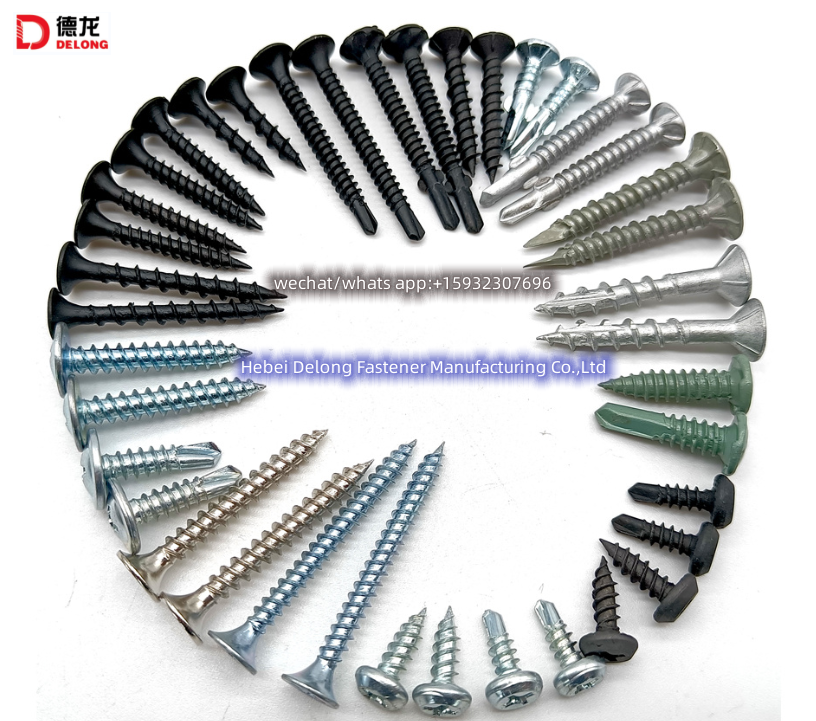

Self-tapping screws are an essential component in various industries, particularly in construction, automotive, electronics, and general manufacturing. Their ability to create their own threads when driven into materials makes them invaluable for both efficiency and convenience. As a supplier, understanding the types, specifications, and applications of self-tapping screws is crucial for meeting customer demands and ensuring product quality.

Types of Self-Tapping Screws

There are several variations of self-tapping screws tailored for specific applications. The most common types include

1. Standard Self-Tapping Screws Typically made from steel, these screws have a sharp point that allows them to penetrate materials like wood and metal without the need for a pre-drilled hole. They are widely used in cabinetry and furniture assembly.

2. Self-Drilling Screws These include a drill bit tip, allowing them to not only tap but also drill through thin sheets of metal and other tough materials. They are particularly popular in metalworking and when joining metal to wood.

3. Thread-Cutting Screws Designed for softer materials, such as plastics and thin woods, these screws create their own threads by cutting into the material rather than forming them. They are widely used in electronics and applications where aesthetic appearance is vital.

4. Self-Sealing Screws These are engineered to create a watertight seal, making them ideal for outdoor applications and equipment exposed to the elements.

Specifications of Self-Tapping Screws

When selecting self-tapping screws for various applications, suppliers need to consider several specifications

- Material Common materials include carbon steel, stainless steel, and sometimes brass or plastic. Stainless steel is preferred in corrosive environments due to its resistance to rust and oxidation. - Coating Coatings such as zinc plating, black oxide, or polymer coatings enhance corrosion resistance and can improve the screw's overall appearance.

self tapping screw chart suppliers

- Head Type The choice of head type—such as pan, flat, or hex—is critical for the intended usage. For instance, pan heads provide a large bearing surface, while countersunk heads offer a flush finish.

- Drive Type Options include Phillips, slotted, Torx, and square, each offering different advantages in terms of grip and torque during installation.

- Size and Length Choosing the right size and length is essential to ensure proper anchoring without damaging the material.

Applications of Self-Tapping Screws

Self-tapping screws are used in many applications due to their versatility. In the construction industry, they are essential for fastening drywall, roofing, and siding. In automotive manufacturing, they are common in assembling components like body panels and trim. Electronics manufacturers rely on self-tapping screws for securing housings and other parts that require a reliable fastening method.

Benefits of Working with Reliable Suppliers

For suppliers, offering a comprehensive range of self-tapping screws with varied specifications can differentiate them in a competitive market. Partnering with manufacturers who adhere to stringent quality control practices ensures that the products available meet industry standards.

When suppliers maintain an up-to-date inventory and respond promptly to customer inquiries, they build trust and reliability in their brand. Providing educational resources or technical support about the different types and their appropriate applications can further enhance customer relations.

Conclusion

In conclusion, self-tapping screws play a critical role across various industries, and understanding their types, specifications, and applications is vital for suppliers. By offering a diverse inventory and maintaining high-quality standards, suppliers can meet the evolving needs of their customers, ensuring a steady demand for these indispensable fasteners. As industries continue to innovate, the relevance of self-tapping screws will remain prominent, and suppliers who adapt to these changes will thrive in the marketplace.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024