self drilling screw driver manufacturer

The Evolution of Self-Drilling Screw Drivers A Comprehensive Guide

In the landscape of modern construction and assembly, self-drilling screws have transformed the way projects are approached. With the advent of self-drilling screw drivers, manufacturers have seen increased efficiency and productivity across various industries. This article explores the significance of self-drilling screw driver manufacturers, the technology behind these tools, and their impact on different sectors.

Understanding Self-Drilling Screws

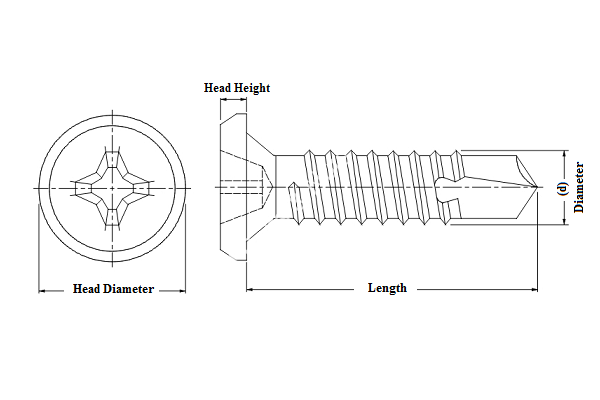

Self-drilling screws are specialized fasteners equipped with a drill point that allows them to bore into materials without the need for a pre-drilled hole. This self-tapping ability simplifies the fastening process and reduces the time and labor involved in assembly. These screws are commonly used in applications such as metal roofing, construction frames, and furniture assembly, where speed and structural integrity are crucial.

The Role of Self-Drilling Screw Driver Manufacturers

The manufacturing of self-drilling screw drivers is a specialized domain that combines engineering excellence with innovative technology. These manufacturers focus on developing tools that enhance the performance of self-drilling screws. The precision of the screwdriver is vital, as it ensures the screws are driven at the correct angle and depth to provide maximum holding power.

Manufacturers invest heavily in research and development to refine the design and functionality of self-drilling screw drivers. This includes optimizing the torque settings, improving grip ergonomics, and utilizing durable materials that can withstand rigorous work conditions. Advanced features such as variable speed control, automatic torque cut-off, and integrated LED lighting for improved visibility are also becoming more prevalent in newer models.

Advancements in Technology

self drilling screw driver manufacturer

With the rise of automation and smart technology, self-drilling screw driver manufacturers are integrating advanced features that enhance usability and efficiency. For instance, some modern drivers come equipped with smart sensors that detect material density and adjust the drilling speed accordingly. This allows users to work seamlessly across different materials, from soft wood to hard metals, without damaging the screws or the workpiece.

Another trend is the development of battery-powered, cordless screwdrivers that offer greater flexibility without sacrificing power. These tools provide easily transportable solutions for professionals in the field, eliminating the constraints of cords and allowing for greater maneuverability in tight spaces.

The Impact on Industries

The impact of self-drilling screw drivers extends across various industries. In construction, the ability to quickly and effectively secure materials leads to faster project completion times. This efficiency not only reduces labor costs but also enhances project quality, as well-anchored components are less likely to shift or fail over time.

In manufacturing settings, self-drilling screw drivers facilitate the rapid assembly of products, allowing manufacturers to scale production and meet varying demand levels efficiently. Industries such as furniture and appliances benefit from self-drilling screws due to their ability to provide strong joints in esthetically pleasing ways.

Conclusion

The evolution of self-drilling screw drivers is a testament to how innovation can simplify processes and improve productivity in various fields. As manufacturers continue to push the boundaries of technology and design, we can expect even greater advancements in this area. This will ultimately lead to the development of tools that not only enhance performance but also contribute positively to sustainable practices by reducing material waste and energy consumption. As the demand for efficiency and quality grows, self-drilling screw driver manufacturers will play a critical role in shaping the future of construction and assembly worldwide.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024