Jan . 09, 2025 11:28

Back to list

screw manufacturer

Finding the right screw manufacturer for your business can significantly impact the quality and reliability of your products. As someone who has navigated the complexities of sourcing components from global suppliers, I can attest to the pivotal role a dependable screw manufacturer plays in production efficacy and product excellence.

Authoritativeness is demonstrated through certifications and standards compliance. A reputable screw manufacturer will adhere to international quality standards such as ISO, ensuring their production processes meet globally recognized benchmarks. Furthermore, you should seek a partner who participates in relevant industry associations and who contributes to the advancement of screw manufacturing technologies. This engagement in the global discourse on production not only highlights their active role in shaping industry standards but also their commitment to maintaining a high level of quality and innovation. Trustworthiness cannot be overstated. Transparent business practices, consistent communication, and a robust quality assurance process are tell-tale signs of a manufacturer you can rely on. They should provide clear documentation of their production methods, quality tests, and delivery timelines. Partnering with a trustworthy manufacturer reduces the risk of costly production setbacks and enhances your overall product reliability. In the increasingly competitive market landscape, the decision to choose the right screw manufacturer should be made with an eye towards long-term partnership. The benefits of such a partnership are tangible improved product performance, reduced time-to-market, and enhanced customer satisfaction. By emphasizing experience, expertise, authoritativeness, and trustworthiness in your selection process, you ensure your business is not only meeting current production demands but is also positioned for future growth and innovation. In doing so, your products are not just assembled with parts but enriched with the legacy of quality manufacturing excellence.

Authoritativeness is demonstrated through certifications and standards compliance. A reputable screw manufacturer will adhere to international quality standards such as ISO, ensuring their production processes meet globally recognized benchmarks. Furthermore, you should seek a partner who participates in relevant industry associations and who contributes to the advancement of screw manufacturing technologies. This engagement in the global discourse on production not only highlights their active role in shaping industry standards but also their commitment to maintaining a high level of quality and innovation. Trustworthiness cannot be overstated. Transparent business practices, consistent communication, and a robust quality assurance process are tell-tale signs of a manufacturer you can rely on. They should provide clear documentation of their production methods, quality tests, and delivery timelines. Partnering with a trustworthy manufacturer reduces the risk of costly production setbacks and enhances your overall product reliability. In the increasingly competitive market landscape, the decision to choose the right screw manufacturer should be made with an eye towards long-term partnership. The benefits of such a partnership are tangible improved product performance, reduced time-to-market, and enhanced customer satisfaction. By emphasizing experience, expertise, authoritativeness, and trustworthiness in your selection process, you ensure your business is not only meeting current production demands but is also positioned for future growth and innovation. In doing so, your products are not just assembled with parts but enriched with the legacy of quality manufacturing excellence.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

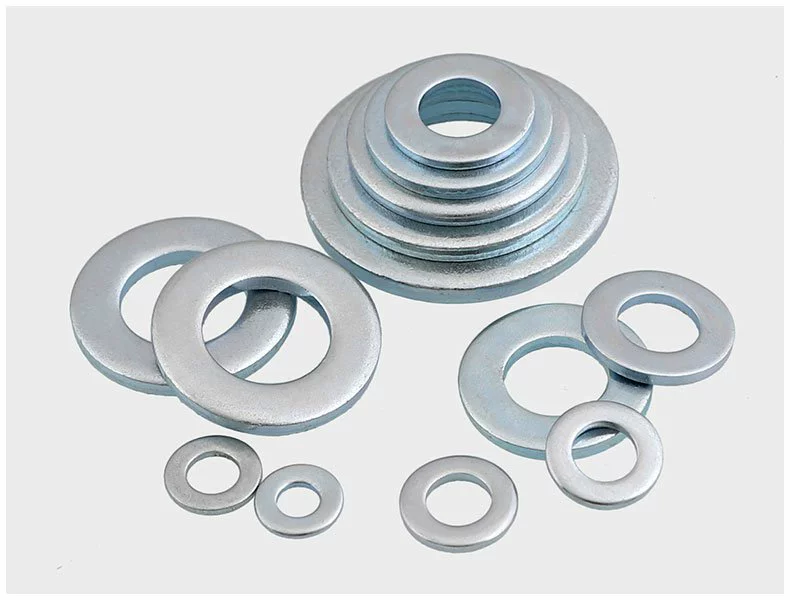

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News