Directly Attaching Screws to Drywall Without Additional Support in Manufacturing Environments

Screwing Directly into Drywall A Guide for Factories and Workshops

When it comes to building and renovation projects, drywall is a staple material known for its versatility and ease of use. For factories and workshops, understanding how to properly install and secure items to drywall is crucial for efficiency and safety. One common method is to screw directly into drywall, which if done correctly, can create strong connections for various applications.

Understanding Drywall Composition

Drywall, also known as gypsum board, consists of a gypsum core sandwiched between two sheets of heavy paper. This combination makes it lightweight and easy to handle but also leaves it vulnerable if not treated with care. The surface of drywall can support a fair amount of weight, but the installation technique and the type of fasteners used are critical factors in determining how much load it can ultimately bear.

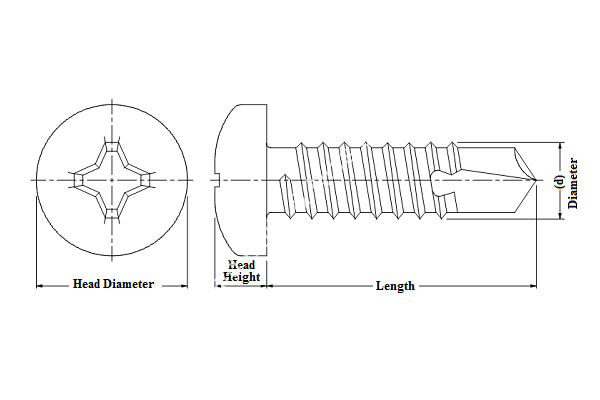

Types of Screws for Drywall

When screwing directly into drywall, not all screws are created equal. Traditional wood screws are not ideal because they do not hold well in the softer material of drywall. Instead, specialized drywall screws, typically made of hardened steel with a bugle-shaped head, are recommended. These screws have deeper threads that provide better grip and stability.

Additionally, for heavy loads, it may be beneficial to use toggle bolts or molly bolts. These options are designed to expand once inserted into the wall cavity, providing a stronger anchorage for heavier items such as shelving, tools, or machinery accessories.

Proper Techniques for Screw Installation

1. Identify Studs Before screwing into drywall, it's critical to locate the underlying studs. Using a stud finder can make this task easier. Attaching screws directly to a stud offers more support than relying solely on drywall. When installing something heavy, aim for a stud to maximize strength and minimize the risk of damaging the drywall.

screw directly into drywall factories

2. Drill Pilot Holes If you're using larger screws, drilling pilot holes can help prevent the drywall from cracking. A pilot hole gives the screw a starting point, allowing for easier installation and reducing the risk of damage to surrounding areas.

3. Screw Depth When driving screws, particularly drywall screws, ensure they are set just below the surface of the drywall. If the screws protrude, they can create an uneven surface and increase the risk of damaging the drywall when painting or applying additional finishes.

4. Use the Right Screw Length The length of the screw is determined by the thickness of the drywall itself and the weight of the item being hung. Generally, a 1.25-inch screw is sufficient for standard ½-inch drywall, while heavier items may require longer screws.

Considerations for Heavy Items

For items that are particularly heavy or require additional reinforcement

- Use Anchors Heavy-duty drywall anchors can be installed before screwing in items. They provide additional security, distributing the weight more evenly and preventing the drywall from tearing.

- Spread the Load If possible, distribute heavy items across multiple screws or anchors. This reduces the overall load on any single point and decreases the likelihood of failure.

Conclusion

Screwing directly into drywall can be a straightforward process when proper techniques and materials are utilized. For factories and workshops, this knowledge is essential in creating efficient workspace setups without compromising on safety. By selecting the right screws, identifying studs, and employing adequate reinforcement methods, businesses can ensure their installations are secure and effective. Understanding these principles not only enhances workshop functionality but also fosters a safer working environment for everyone involved.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024