Feb . 12, 2025 01:11

Back to list

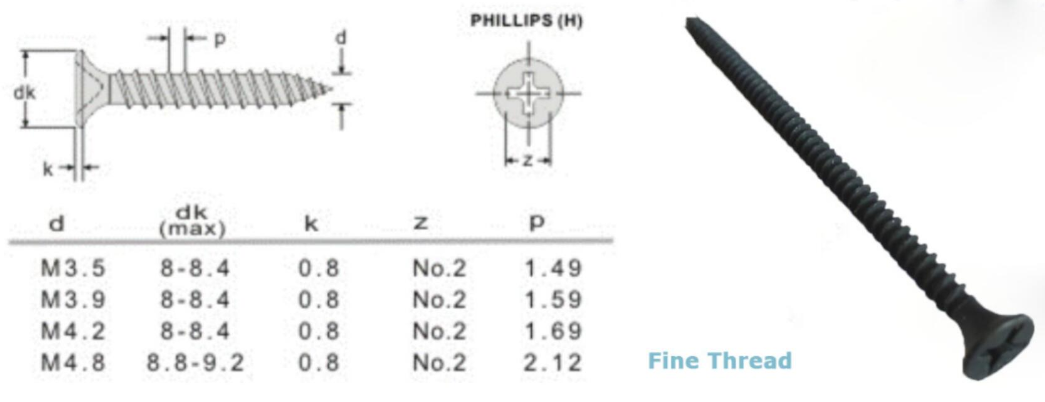

csk head self tapping screw

When embarking on a project that involves the use of self-tapping screws, understanding the importance and precise execution of a pilot hole is critical. Self-tapping screws, recognized for their capacity to tap their threads into materials, are widely used in construction, manufacturing, and DIY projects. Yet, their remarkable efficiency is only realized when paired with appropriately-sized pilot holes.

Trustworthiness of advice in this scope also extends to selecting quality tools. A contractor once noted substantial difference in outcome when using premium pilot hole drill bits over generic ones. Inferior bits cause irregularities in hole diameter, reducing the screw’s ability to maintain a tight grip. Thus, investing in high-quality tools garners consistent reliability and performance. Moreover, acknowledging variations in material composition is crucial. A softer material, like PVC, may require a pilot hole at the smaller end of the suggested range to ensure optimal thread engagement without damaging the material. Conversely, attempting to tap into harder materials, such as aluminum, benefits from pilot holes on the larger end of the spectrum, allowing the screw to effortlessly carve its path without resistance leading to metal fatigue. A comprehensive understanding of pilot holes fosters a superior end-product. Case studies within manufacturing environments have highlighted that precise pilot hole execution directly correlates with reduced material wastage and enhanced assembly efficiency. Removal of guesswork implicitly improves the overall project workflow, ensuring quality and adherence to project timelines. In conclusion, mastering the art of pilot holes for 8 self-tapping screws not only requires attention to size and technique but also an integration of experience and authoritative resources. Precision, coupled with informed tool choices, translates into installations that withstand the test of time, supporting structural integrity and facilitating ease of future maintenance. As experts continue to explore and innovate within fastener technology, the core tenets associated with pilot holes and their functional coexistence with self-tapping screws remain steadfast in their significance.

Trustworthiness of advice in this scope also extends to selecting quality tools. A contractor once noted substantial difference in outcome when using premium pilot hole drill bits over generic ones. Inferior bits cause irregularities in hole diameter, reducing the screw’s ability to maintain a tight grip. Thus, investing in high-quality tools garners consistent reliability and performance. Moreover, acknowledging variations in material composition is crucial. A softer material, like PVC, may require a pilot hole at the smaller end of the suggested range to ensure optimal thread engagement without damaging the material. Conversely, attempting to tap into harder materials, such as aluminum, benefits from pilot holes on the larger end of the spectrum, allowing the screw to effortlessly carve its path without resistance leading to metal fatigue. A comprehensive understanding of pilot holes fosters a superior end-product. Case studies within manufacturing environments have highlighted that precise pilot hole execution directly correlates with reduced material wastage and enhanced assembly efficiency. Removal of guesswork implicitly improves the overall project workflow, ensuring quality and adherence to project timelines. In conclusion, mastering the art of pilot holes for 8 self-tapping screws not only requires attention to size and technique but also an integration of experience and authoritative resources. Precision, coupled with informed tool choices, translates into installations that withstand the test of time, supporting structural integrity and facilitating ease of future maintenance. As experts continue to explore and innovate within fastener technology, the core tenets associated with pilot holes and their functional coexistence with self-tapping screws remain steadfast in their significance.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

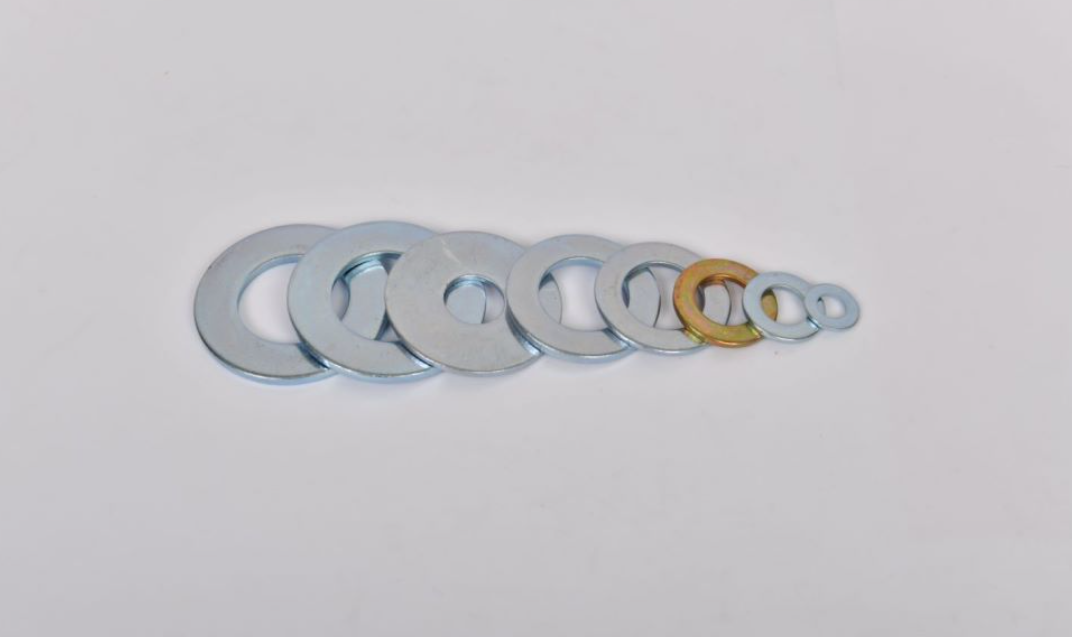

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News