pan head self drilling screw manufacturer exporter

Exploring the Role of Pan Head Self-Drilling Screw Manufacturers and Exporters

In the ever-evolving world of construction and manufacturing, the demand for high-quality fastening solutions has risen dramatically. Among these solutions, pan head self-drilling screws have gained significant traction due to their versatility and efficiency. As industry requirements continue to advance, the role of pan head self-drilling screw manufacturers and exporters has become increasingly crucial. This article delves into the characteristics of these screws, the manufacturing process, and the vital role of exportation in a globalized market.

What are Pan Head Self-Drilling Screws?

Pan head self-drilling screws are designed with a flat, rounded head that provides a clean finish and a larger bearing surface. Unlike regular screws, these screws come equipped with a drill point, which allows them to penetrate through materials without the need for a pre-drilled hole. This feature not only saves time but also enhances precision when fastening materials like metal, wood, or plastic. The unique design makes them an ideal choice for various applications, from home improvement projects to industrial constructions.

The Manufacturing Process

The manufacturing of pan head self-drilling screws involves several stages, beginning with the selection of high-quality raw materials. Typically, manufacturers opt for materials such as carbon steel, stainless steel, or even specialized alloys, depending on the application and environment where the screws will be used.

Once the materials are selected, the process kicks off with wire drawing, where steel is drawn into thinner wire suitable for screw manufacturing. This is followed by the cold heading process, where the wire is shaped into the initial form of a screw using high pressure. After the heads of the screws are formed, the drill points are created through precision machinery.

Heat treatment is another critical stage that affects the screws' performance. This process strengthens the screws and enhances their corrosion resistance. Finally, the screws undergo surface treatment, which may include coating with zinc, black oxide, or other protective layers to improve durability and resistance to environmental factors.

Quality Control and Standards

pan head self drilling screw manufacturer exporter

Quality control is paramount in the manufacturing of pan head self-drilling screws. Manufacturers must adhere to international standards and specifications to ensure that their products are reliable and safe for use. Regular inspections and testing for tensile strength, corrosion resistance, and dimensional accuracy help maintain high-quality standards.

ISO certifications and other industry-related certifications are essential indicators of a manufacturer’s commitment to quality. By obtaining these certifications, manufacturers can enhance their credibility and competitiveness in the global market.

The Role of Exporters

With the rise of globalization, the role of exporters in the pan head self-drilling screw industry has become increasingly significant. Exporters serve as intermediaries, bridging the gap between manufacturers and international markets. They ensure compliance with various regulations and standards that differ from country to country, making it easier for manufacturers to reach a wider audience.

Exporting pan head self-drilling screws opens up numerous opportunities for manufacturers. Not only does it enable them to diversify their revenue streams, but it also helps them to build brand recognition on a global scale. Understanding market demands in different regions allows manufacturers and exporters to tailor their products to suit specific requirements, making their offerings more appealing to customers.

Market Trends and Future Outlook

As industries continue to evolve, the demand for innovative fastening solutions like pan head self-drilling screws is expected to expand. Advances in technology may lead to the development of even more efficient and durable screws, catering to modern construction methods and materials. Additionally, increasing awareness towards sustainable manufacturing processes will influence new manufacturers to adopt eco-friendly practices.

In conclusion, pan head self-drilling screw manufacturers and exporters play a pivotal role in meeting the growing demands of various industries. Through rigorous manufacturing processes, adherence to quality standards, and strategic exportation, they create and deliver essential fastening solutions that contribute significantly to the construction and manufacturing sectors. As the market continues to evolve, these key players will undoubtedly shape the future of fastening technology.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

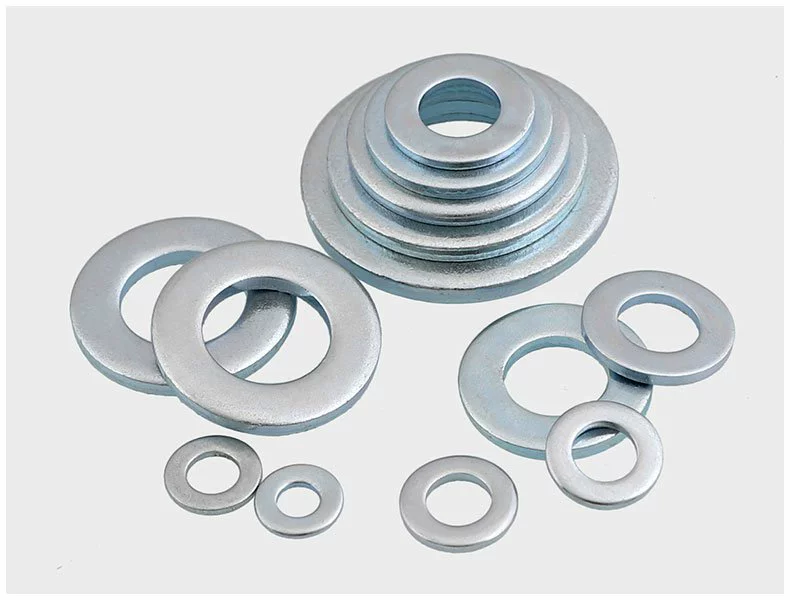

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024