m4 self tapping screw dimensions exporter

Understanding M4 Self-Tapping Screw Dimensions for Exporters

In the world of manufacturing and assembly, self-tapping screws are critical components that facilitate the joining of materials without the need for pre-drilled holes. Among the various sizes and types, M4 self-tapping screws hold a significant position, particularly for exporters who cater to industries demanding precision and reliability. This article delves into the dimensions, specifications, and considerations for M4 self-tapping screws aimed at international trade.

What are M4 Self-Tapping Screws?

The designation M4 refers to screws that have a nominal diameter of 4 millimeters. Self-tapping screws are designed to create their own thread in the material they are driven into, which makes them a preferred choice for various applications, from woodworking to metal fabrication. These screws are particularly valuable in industries such as automotive, electronics, and construction, where fasteners must offer durability and ease of installation.

Key Dimensions of M4 Self-Tapping Screws

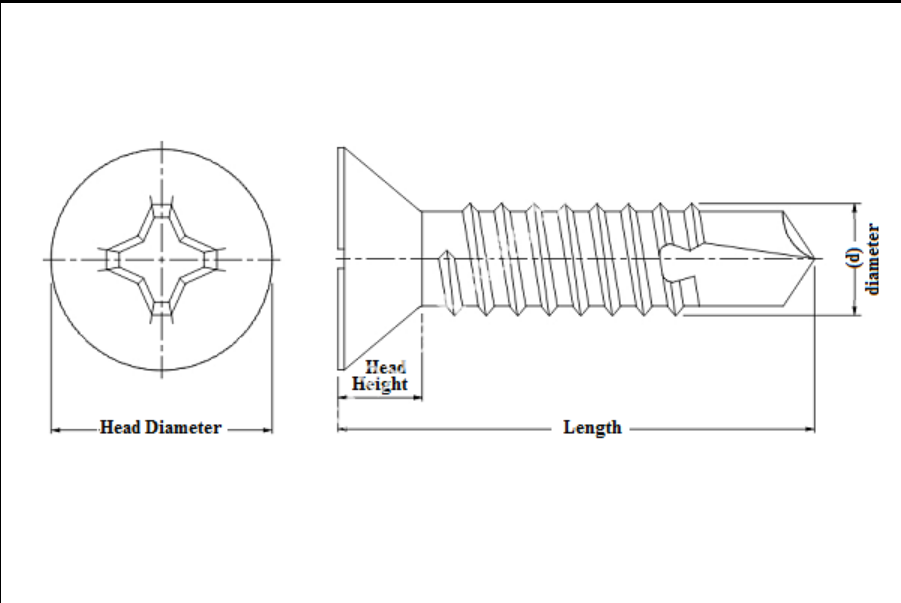

When catering to export requirements, understanding the dimensions and specifications of M4 self-tapping screws is crucial. The inherent properties of these screws are characterized by several key measurements

1. Diameter As mentioned, the major diameter of an M4 screw is 4 mm. This diameter is essential for ensuring compatibility with the tools and substrates used in assembly.

2. Length The length of M4 self-tapping screws can vary widely based on application requirements, typically ranging from 10 mm to 100 mm or more. Exporters must offer a range of lengths to meet the diverse needs of their clients.

3. Thread Pitch The standard thread pitch for an M4 screw is usually 0.7 mm, although variations can exist. The thread pitch determines how tightly a screw can grip the material, affecting the overall stability of the joint.

4. Head Type M4 self-tapping screws come in a variety of head styles including pan, flat, round, and hex heads. Each type offers unique advantages regarding aesthetics, torque application, and ease of use.

5. Drive Type Common drive types for M4 screws include Phillips, slotted, and Torx. Each drive style contributes to how the screw is installed or removed, influencing user convenience and tool compatibility.

m4 self tapping screw dimensions exporter

6. Material and Finish The choice of materials, such as stainless steel, carbon steel, or brass, along with protective coatings (like zinc plating), impacts the screws’ corrosion resistance, strength, and overall performance.

Considerations for Exporters

When exporting M4 self-tapping screws, several factors must be considered to ensure compliance with international standards and customer satisfaction

- Quality Standards Meeting standards such as ISO 9001 can enhance credibility and assure clients of the product quality. It's vital to have thorough quality control processes in place.

- Packaging Proper packaging not only protects screws during transit but also influences purchasing decisions. Clear labeling and sustainable packaging solutions can improve marketability.

- Regulatory Compliance Exporters must be aware of regulations in destination markets, including material restrictions and safety standards. This compliance can help avoid delays and penalties.

- Market Research Understanding the demands of specific markets allows exporters to tailor their offerings. Whether it is the automotive sector in Europe or construction in Asia, a targeted approach can yield better results.

- Logistics and Supply Chain Efficient logistics are essential for timely deliveries. Establishing reliable supply chain partnerships can facilitate smoother operations and improve customer satisfaction.

Conclusion

M4 self-tapping screws are essential fasteners that serve various industries, making them significant for exporters. Understanding their dimensions and specifications, alongside considering market trends and compliance requirements, is vital for successful international trade. By focusing on quality, packaging, and efficient logistics, exporters can capitalize on the growing demand for these versatile fasteners, ensuring that they meet the precise needs of their clients while driving their own business success.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024