Feb . 16, 2025 13:07

Back to list

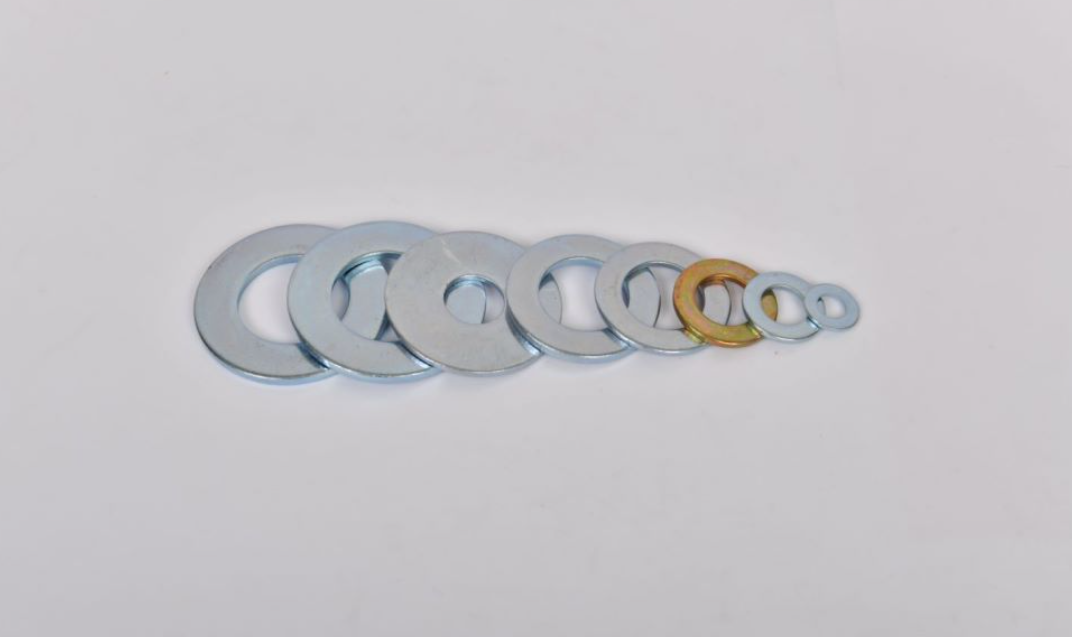

flat washer m4

When selecting the right flat washer for your assembly, especially those marked with the M4 specification, understanding the subtle yet critical attributes of these components can significantly impact the efficiency and reliability of your projects. Renowned for their simplicity, flat washers serve an essential function in distributing loads, reducing wear, and protecting surfaces during fastening processes.

In applications wherein aesthetics matter as much as functionality, the finishing of M4 washers also comes into play. Surface treatments, like galvanization or powder coating, not only enhance the washer's resistance to environmental factors but can be tailored to blend seamlessly with the assembly's design. These options impart a professional look while ensuring longevity, a testament to how selecting the right flat washer envelops both form and function seamlessly. A deep dive into the authoritative scope of flat washers, particularly those like the M4, reveals their pivotal role in harmonizing the components' mechanical synergy. They have established themselves as invaluable assets across industries that value precision—from automotive to electronics. Given the washer's fundamental role, it is not merely a matter of choosing an accessory but making an informed decision that affects the entire machinery's operability. Trustworthiness in selecting flat washers comes from partnering with reputable manufacturers known for their rigorous quality controls. It ensures that every batch of washers meets stringent standards, thus safeguarding against the pitfalls of using subpar materials that might compromise the assembly's durability. By investing in certified M4 flat washers, users stand assured of their investment returning in terms of reduced maintenance costs and enhanced equipment lifespan. In conclusion, the M4 flat washer is far more than a passive component. By distributing stress, reducing surface friction, and protecting against environmental degradation, it underpins the structural security of assemblies. Whether for a humble home project or an institutional installation, understanding and choosing the right type of M4 flat washer—as demonstrated by experience and expertise—reinforces the entire foundation on which mechanical operations rely. The breadth of choice available ensures that there is an M4 washer suited for each unique need, underscoring its indispensable value in both the present and future of assembly solutions.

In applications wherein aesthetics matter as much as functionality, the finishing of M4 washers also comes into play. Surface treatments, like galvanization or powder coating, not only enhance the washer's resistance to environmental factors but can be tailored to blend seamlessly with the assembly's design. These options impart a professional look while ensuring longevity, a testament to how selecting the right flat washer envelops both form and function seamlessly. A deep dive into the authoritative scope of flat washers, particularly those like the M4, reveals their pivotal role in harmonizing the components' mechanical synergy. They have established themselves as invaluable assets across industries that value precision—from automotive to electronics. Given the washer's fundamental role, it is not merely a matter of choosing an accessory but making an informed decision that affects the entire machinery's operability. Trustworthiness in selecting flat washers comes from partnering with reputable manufacturers known for their rigorous quality controls. It ensures that every batch of washers meets stringent standards, thus safeguarding against the pitfalls of using subpar materials that might compromise the assembly's durability. By investing in certified M4 flat washers, users stand assured of their investment returning in terms of reduced maintenance costs and enhanced equipment lifespan. In conclusion, the M4 flat washer is far more than a passive component. By distributing stress, reducing surface friction, and protecting against environmental degradation, it underpins the structural security of assemblies. Whether for a humble home project or an institutional installation, understanding and choosing the right type of M4 flat washer—as demonstrated by experience and expertise—reinforces the entire foundation on which mechanical operations rely. The breadth of choice available ensures that there is an M4 washer suited for each unique need, underscoring its indispensable value in both the present and future of assembly solutions.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News