custom self tapping rivet screw

Custom Self-Tapping Rivet Screws A Comprehensive Overview

In the ever-evolving landscape of construction, manufacturing, and automotive industries, the need for reliable fastening solutions has never been more critical. Among the myriad options available in the market, custom self-tapping rivet screws have emerged as a popular choice, offering unparalleled benefits that cater to the specific needs of various applications. This article delves into the characteristics, advantages, and applications of custom self-tapping rivet screws, highlighting their importance in modern fastening technologies.

Understanding Self-Tapping Rivet Screws

Self-tapping rivet screws are specialized fasteners designed to create their own thread as they are driven into materials, making them an ideal solution for a wide range of applications. Typically made of durable materials like steel, aluminum, or stainless steel, these screws combine the functionalities of rivets and screws, providing secure and permanent fastening.

The self-tapping feature eliminates the need for pre-drilling or tapping threads, significantly simplifying the assembly process. This not only saves time but also reduces labor costs, making it a cost-effective solution for manufacturers and contractors alike.

Customization Options

One of the standout features of self-tapping rivet screws is their customizability. Depending on the application, customers can request specific dimensions, materials, and coatings to meet their unique requirements. Customization can include

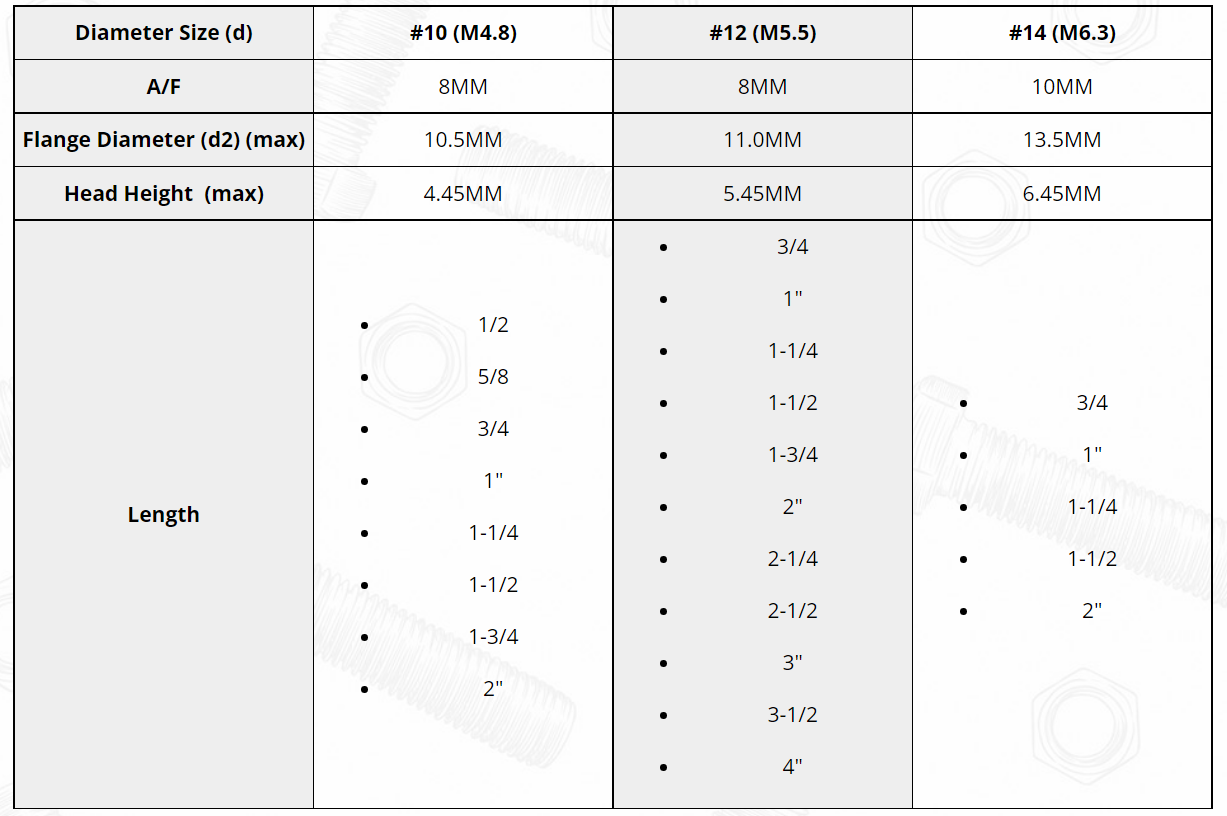

1. Size and Length Clients can select from a variety of sizes and lengths to suit different materials and thicknesses.

2. Coating To enhance corrosion resistance and longevity, custom coatings such as zinc plating, anodizing, or powder coating can be applied.

3. Head Styles Various head styles, such as flat, pan, or hex heads, can be customized based on aesthetic preferences or functional necessities.

custom self tapping rivet screw

This level of customization ensures that self-tapping rivet screws can be tailored to meet the exact specifications of any project, resulting in more efficient and reliable fastening.

Advantages of Custom Self-Tapping Rivet Screws

1. Ease of Use The self-tapping feature means that these screws can be driven directly into materials without pre-drilling, which simplifies the installation process. This results in faster assembly times, allowing projects to progress more swiftly.

2. Strong and Durable Once installed, self-tapping rivet screws provide a tight grip that is resistant to vibrations and heavy loads. Their robust construction ensures longevity, making them suitable for use in high-stress environments.

3. Versatility These screws can be used in various materials, including wood, metal, plastics, and composites. This versatility makes them ideal for a multitude of applications, from automotive assembly to building construction and electronic device manufacturing.

4. Cost-Effectiveness By reducing the need for multiple tools and additional labor associated with pre-drilling, custom self-tapping rivet screws can lower overall production costs. Their long-lasting nature further enhances their cost-effectiveness over time.

Applications

Custom self-tapping rivet screws are utilized across various industries, including

- Automotive Ideal for assembling components in vehicles, where strong and lightweight fastening is essential. - Aerospace Used in aircraft manufacturing, where weight reduction and reliability are crucial. - Construction Essential in building frameworks, where they provide quick and efficient fastening of metal or wood structures. - Electronics Employed in securing casings and mounting components in electronic devices, ensuring safety and stability.

Conclusion

Custom self-tapping rivet screws represent a significant advancement in fastening technology, offering a blend of efficiency, strength, and adaptability. As industries continue to seek innovative solutions to enhance productivity and reduce costs, the demand for these specialized screws is only set to grow. With their unique ability to be tailored to specific needs, custom self-tapping rivet screws have become an indispensable tool in various applications, driving progress and innovation in modern manufacturing.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024