custom self drilling screw

Custom Self-Drilling Screws A Comprehensive Guide

In the realm of construction and manufacturing, the importance of fasteners cannot be overstated. Among these, self-drilling screws have emerged as a favorite for a variety of applications due to their efficiency and ease of use. Custom self-drilling screws, in particular, are designed to meet specific needs, providing tailored solutions that enhance productivity and reliability.

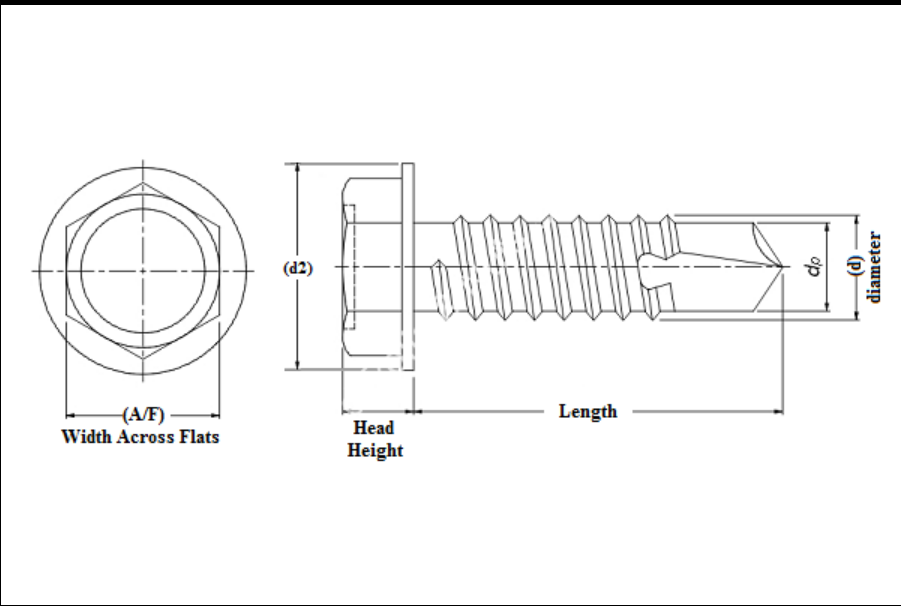

Self-drilling screws are distinguishable by their unique design, featuring a drill-like tip that allows them to create their own hole as they are driven into materials. This eliminates the need for pre-drilling, which can save considerable time and labor in construction and assembly processes. Their ability to cut through metal, wood, and other substrates makes them incredibly versatile, appealing to industries ranging from automotive to building and construction.

Custom Self-Drilling Screws A Comprehensive Guide

The manufacturing process for custom self-drilling screws typically begins with a detailed consultation. Engineers and designers collaborate with customers to understand the application's unique demands, such as load requirements, environmental conditions, and substrate materials. This information is crucial for producing a fastener that not only fits but also performs optimally under specific conditions.

custom self drilling screw

Additionally, advancements in technology have played a significant role in enhancing the production of custom self-drilling screws. Computer-aided design (CAD) software allows for precise and accurate designs, while modern machining techniques enable manufacturers to produce screws with exceptional consistency and quality. As a result, companies can expect a high level of reliability from their custom products, reducing the risk of failure and minimizing waste.

Another important aspect of custom self-drilling screws is their impact on project efficiency. By eliminating the need for pre-drilling and simplifying the fastening process, these screws help workers complete tasks more quickly and efficiently. This speed can lead to cost savings, enabling projects to stay on budget and on schedule.

Moreover, custom self-drilling screws can also prioritize the safety and integrity of the structures they secure. With tailored design options, manufacturers can ensure that the screws exhibit the necessary performance characteristics to withstand various forces and stresses, ultimately contributing to the longevity and safety of the final product.

In conclusion, custom self-drilling screws offer a wealth of benefits to industries that rely on effective fastening solutions. Their unique ability to be tailored to specific requirements enhances both their functionality and application. As technology continues to advance, the production of these customized fasteners will likely evolve, providing even greater efficiency and reliability for future projects. Businesses looking to optimize their construction or manufacturing processes should consider the advantages of incorporating custom self-drilling screws into their systems, leveraging their potential for enhanced performance and cost-effectiveness.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024