Top Self-Tapping Screws for Maximum Performance and Versatility in Your Projects

The Rise of the Biggest Self-Tapping Screw Products Revolutionizing Fastening Solutions

In the world of construction and manufacturing, fasteners play a crucial role in ensuring structural integrity and efficiency. Among the myriad of fasteners available, self-tapping screws have emerged as a game-changing solution. As industries evolve, the demand for bigger and more robust self-tapping screws has surged, setting the stage for innovative products that redefine fastening applications.

Self-tapping screws are designed to create their own hole in the material they are driven into, which eliminates the need for pre-drilling and significantly expedites the assembly process. This feature alone makes them highly desirable in sectors ranging from woodworking to metal fabrication. However, a recent trend has seen manufacturers focusing on the development of larger self-tapping screws to meet the increasing needs of heavy-duty applications.

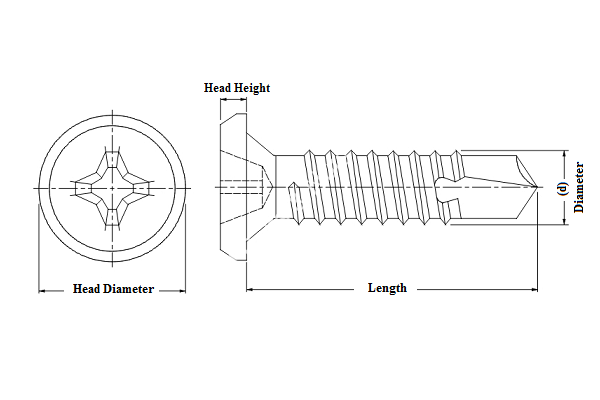

The biggest self-tapping screws on the market are typically made from high-strength materials like stainless steel or carbon steel, designed to withstand significant stresses and loads. These screws are not only larger in diameter but often come with longer lengths to provide more grip and stability. The improved design translates to a significant reduction in failure rates, ensuring that structures remain secure over time.

One of the key applications of these larger self-tapping screws is in the construction of steel frames and large machinery. As companies look to streamline their build processes, integrating bigger self-tapping screws can reduce the number of fasteners required, thereby cutting down on labor costs and installation time. Additionally, the enhanced holding power of these screws means that they can be used in environments subject to vibration and movement, such as in automotive applications or heavy equipment sectors.

biggest self tapping screw product

Furthermore, the advancement in coatings and finishes for self-tapping screws has increased their durability and resistance to corrosion, further broadening their applicability

. Products treated with specialized coatings can withstand harsh environmental conditions, making them ideal for outdoor construction or marine applications.The growth of e-commerce has also propelled the availability of these products, allowing consumers to easily access a variety of self-tapping screws suited for their specific needs. Online platforms provide detailed specifications, user reviews, and pricing comparisons, enabling purchasers to make informed decisions.

In addition to the construction industry, larger self-tapping screws are finding their way into residential applications, such as decking and fencing. Home improvement enthusiasts appreciate the ease of use and reliability that these screws offer, transforming DIY projects and renovations into smoother, more manageable tasks.

To sum up, the rise of the biggest self-tapping screw products signifies a major advancement in fastening technology. Their combination of strength, durability, and ease of use addresses the demands of various industries while enhancing productivity. As we continue to innovate and improve fastening solutions, larger self-tapping screws will likely play a pivotal role in shaping the future of construction and manufacturing. With their growing popularity, they represent not only a trend but a standard for efficiency and reliability in fastening solutions.

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024