Feb . 10, 2025 09:27

Back to list

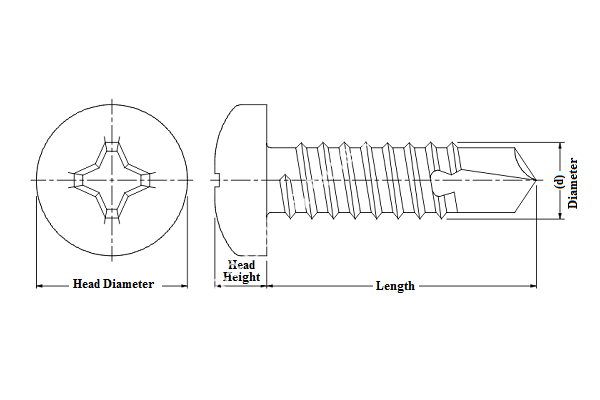

3mm self tapping screw

When it comes to building efficient and reliable products, the choice of components plays a crucial role. Among these components, the humble 3mm self-tapping screw stands out as a versatile and indispensable tool. Its ability to create its own thread in a pre-drilled hole ensures that it provides a strong and reliable hold across a multitude of applications, from DIY projects to industrial manufacturing.

Perhaps most critically, the trustworthiness of a 3mm self-tapping screw can be seen in its track record across numerous projects and industries. Whether used in household appliances, electronics, or automotive assemblies, these screws have proven their capability time and again. Their consistent performance builds confidence in both manufacturers and end-users, providing a trusted solution that withstands the rigors of time and use. For businesses focused on customer satisfaction and product longevity, relying on components that deliver consistent performance is non-negotiable. Choosing the right supplier also plays into the trustworthiness of the product. Leading manufacturers adhere to strict quality control standards, ensuring each screw is produced with precision. This attention to detail in production further bolsters the screw’s reliability once it becomes part of a final product. For engineers and project managers, partnering with reputable suppliers ensures that each component used in their constructions meets high standards of quality and performance, reducing the likelihood of failures and enhancing the product lifecycle. In conclusion, the 3mm self-tapping screw is more than a mere fastener; it is a critical component that supports innovation and craftsmanship across numerous fields. Its application represents a melding of practical experience, technical expertise, authoritative standards, and trustworthy performance. Therefore, when seeking solutions for projects requiring secure and reliable joints, the 3mm self-tapping screw serves as a keystone that stands the test of time and rigorous application.

Perhaps most critically, the trustworthiness of a 3mm self-tapping screw can be seen in its track record across numerous projects and industries. Whether used in household appliances, electronics, or automotive assemblies, these screws have proven their capability time and again. Their consistent performance builds confidence in both manufacturers and end-users, providing a trusted solution that withstands the rigors of time and use. For businesses focused on customer satisfaction and product longevity, relying on components that deliver consistent performance is non-negotiable. Choosing the right supplier also plays into the trustworthiness of the product. Leading manufacturers adhere to strict quality control standards, ensuring each screw is produced with precision. This attention to detail in production further bolsters the screw’s reliability once it becomes part of a final product. For engineers and project managers, partnering with reputable suppliers ensures that each component used in their constructions meets high standards of quality and performance, reducing the likelihood of failures and enhancing the product lifecycle. In conclusion, the 3mm self-tapping screw is more than a mere fastener; it is a critical component that supports innovation and craftsmanship across numerous fields. Its application represents a melding of practical experience, technical expertise, authoritative standards, and trustworthy performance. Therefore, when seeking solutions for projects requiring secure and reliable joints, the 3mm self-tapping screw serves as a keystone that stands the test of time and rigorous application.

Next:

Prev:

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News