Feb . 03, 2025 01:51

Back to list

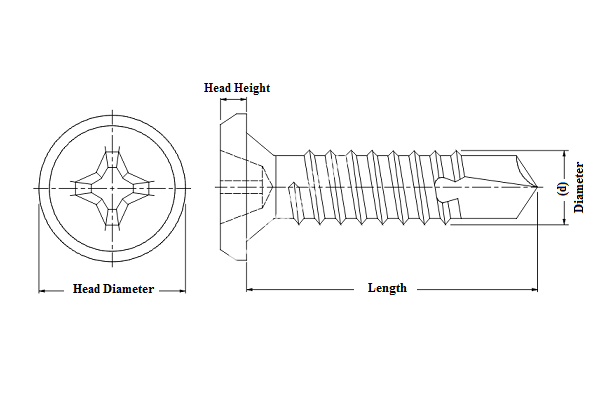

10 self drilling screw

For anyone involved in construction or home improvement projects, the search for the most efficient and reliable fastening solutions often leads to the term 10 self-drilling screw. These screws have become indispensable due to their unique attributes and unmatched performance in a variety of materials. Below, we delve into the reasons why the 10 self-drilling screw stands out, offering insights based on experience and expertise, and highlighting its authoritative place in construction practices.

From a trustworthiness standpoint, the 10 self-drilling screw is often supported by a variety of technical resources and support from manufacturers. These resources include detailed guides on correct installation techniques, load capacities, and material compatibility. This transparency in information assures professionals and DIY enthusiasts alike of the product's capabilities and limitations, fostering informed decision-making in project planning and execution. Moreover, practical experiences shared by users highlight the adaptability of the 10 self-drilling screw. Whether applied in residential roofing, industrial machinery, or commercial frameworks, their versatility is a benefit consistently noted in user reviews. Many have even attested to the cost-effectiveness brought about by reduced labor costs and diminished wear on power tools, attributed to the efficiency of the self-drilling action. This collective feedback further reinforces their standing as a trusted component in construction arsenals worldwide. In conclusion, the 10 self-drilling screw exemplifies the perfect blend of advanced engineering, proven reliability, and industry validation. It stands as a testament to the evolution of construction fasteners, embodying the qualities of experience, expertise, authoritativeness, and trustworthiness. As new challenges in construction emerge, this screw's enduring value reassures its pivotal role in delivering secure and steadfast connections, marking it as an essential item for anyone serious about quality and performance in their projects.

From a trustworthiness standpoint, the 10 self-drilling screw is often supported by a variety of technical resources and support from manufacturers. These resources include detailed guides on correct installation techniques, load capacities, and material compatibility. This transparency in information assures professionals and DIY enthusiasts alike of the product's capabilities and limitations, fostering informed decision-making in project planning and execution. Moreover, practical experiences shared by users highlight the adaptability of the 10 self-drilling screw. Whether applied in residential roofing, industrial machinery, or commercial frameworks, their versatility is a benefit consistently noted in user reviews. Many have even attested to the cost-effectiveness brought about by reduced labor costs and diminished wear on power tools, attributed to the efficiency of the self-drilling action. This collective feedback further reinforces their standing as a trusted component in construction arsenals worldwide. In conclusion, the 10 self-drilling screw exemplifies the perfect blend of advanced engineering, proven reliability, and industry validation. It stands as a testament to the evolution of construction fasteners, embodying the qualities of experience, expertise, authoritativeness, and trustworthiness. As new challenges in construction emerge, this screw's enduring value reassures its pivotal role in delivering secure and steadfast connections, marking it as an essential item for anyone serious about quality and performance in their projects.

Latest news

-

Top Choices for Plasterboard FixingNewsDec.26,2024

-

The Versatility of Specialty WashersNewsDec.26,2024

-

Secure Your ProjectsNewsDec.26,2024

-

Essential Screws for Chipboard Flooring ProjectsNewsDec.26,2024

-

Choosing the Right Drywall ScrewsNewsDec.26,2024

-

Black Phosphate Screws for Superior PerformanceNewsDec.26,2024

-

The Versatile Choice of Nylon Flat Washers for Your NeedsNewsDec.18,2024

Related News